Digital woodworking- remastering traditional joints

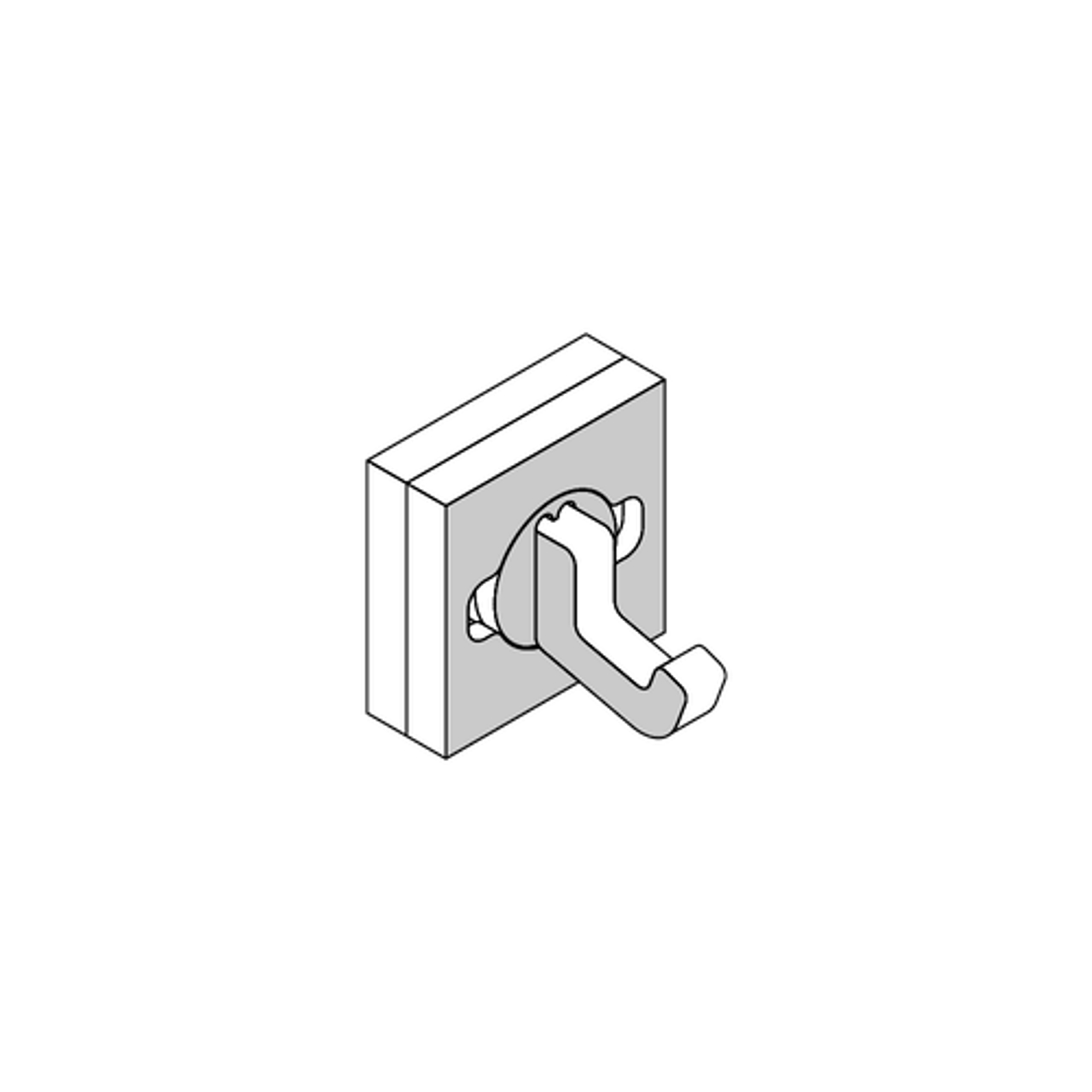

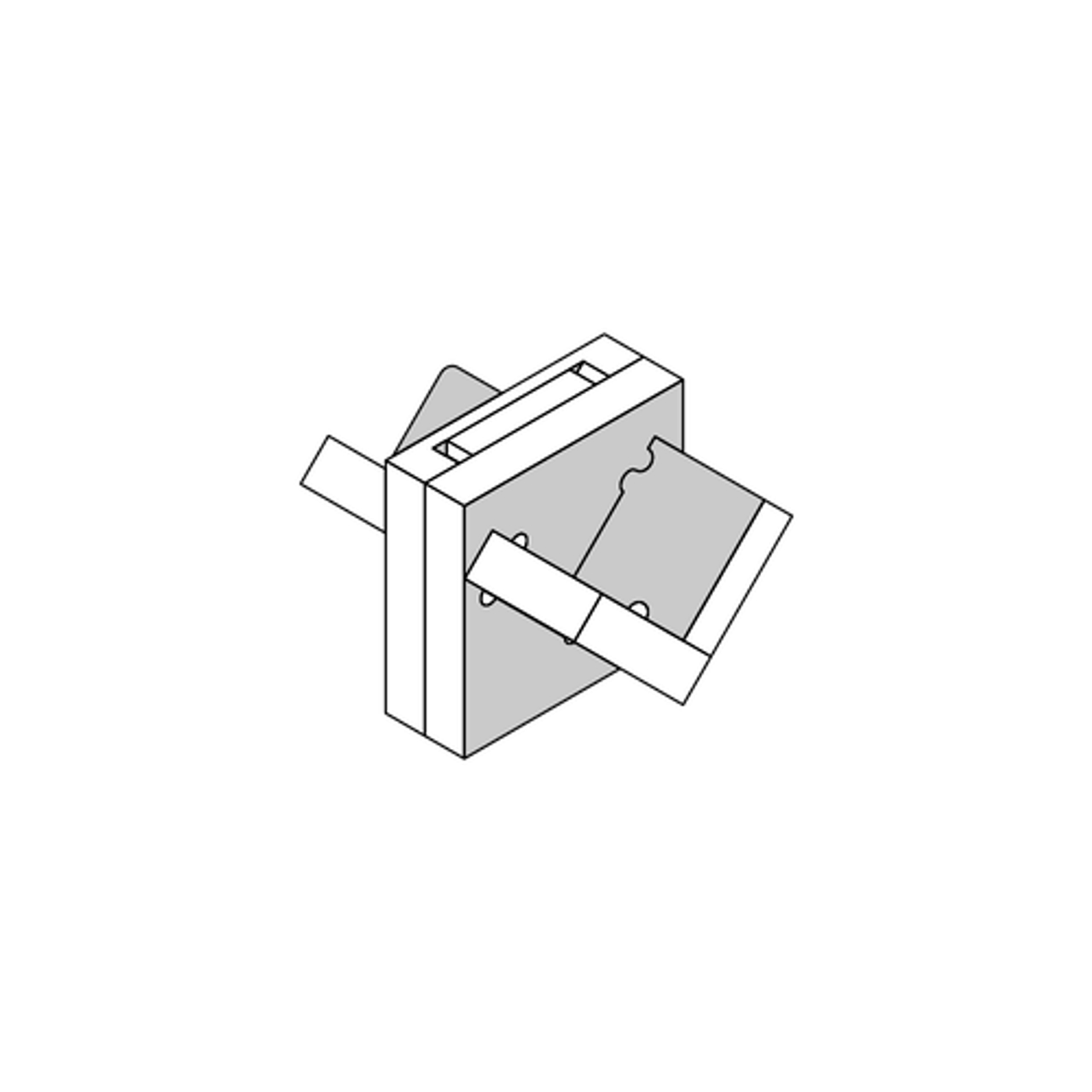

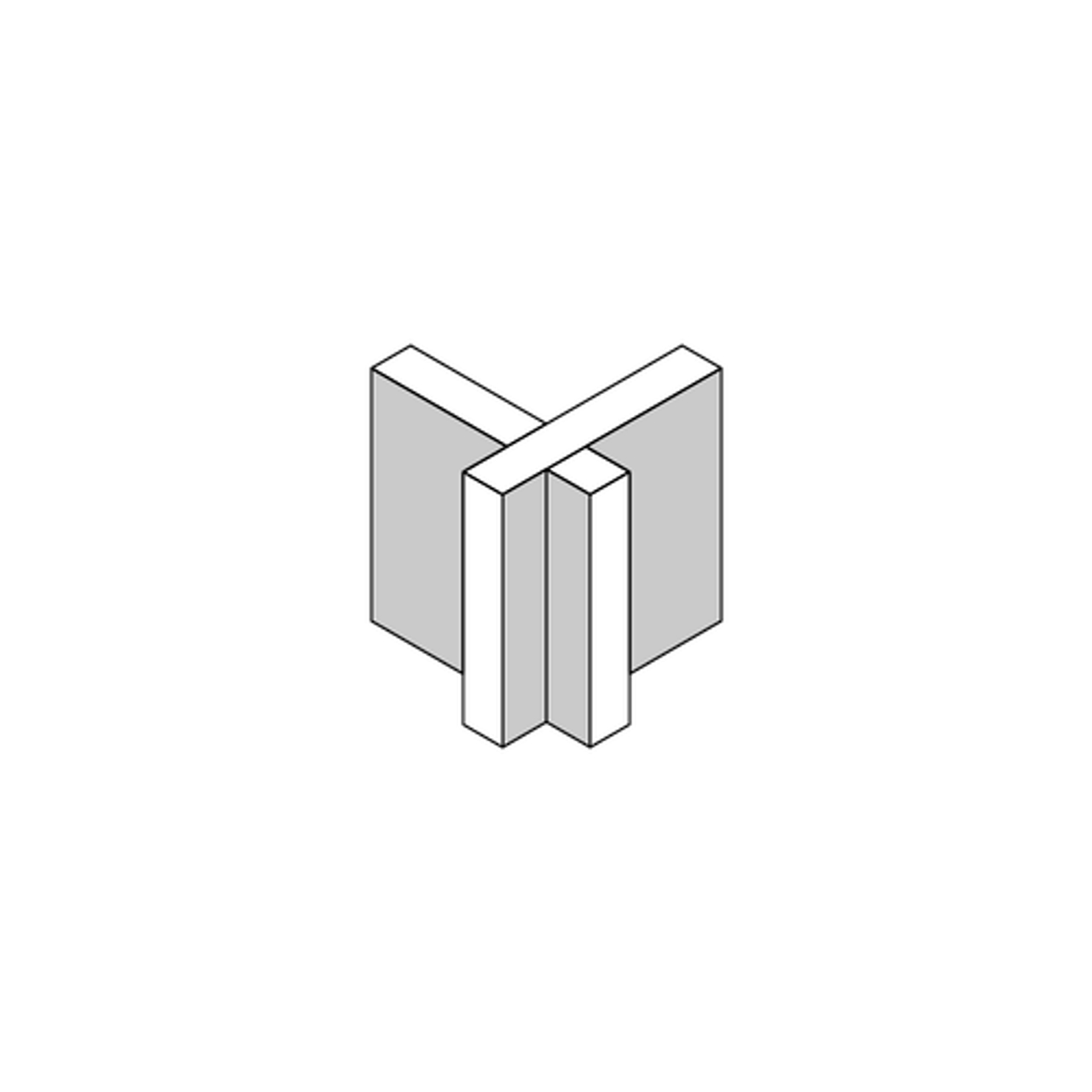

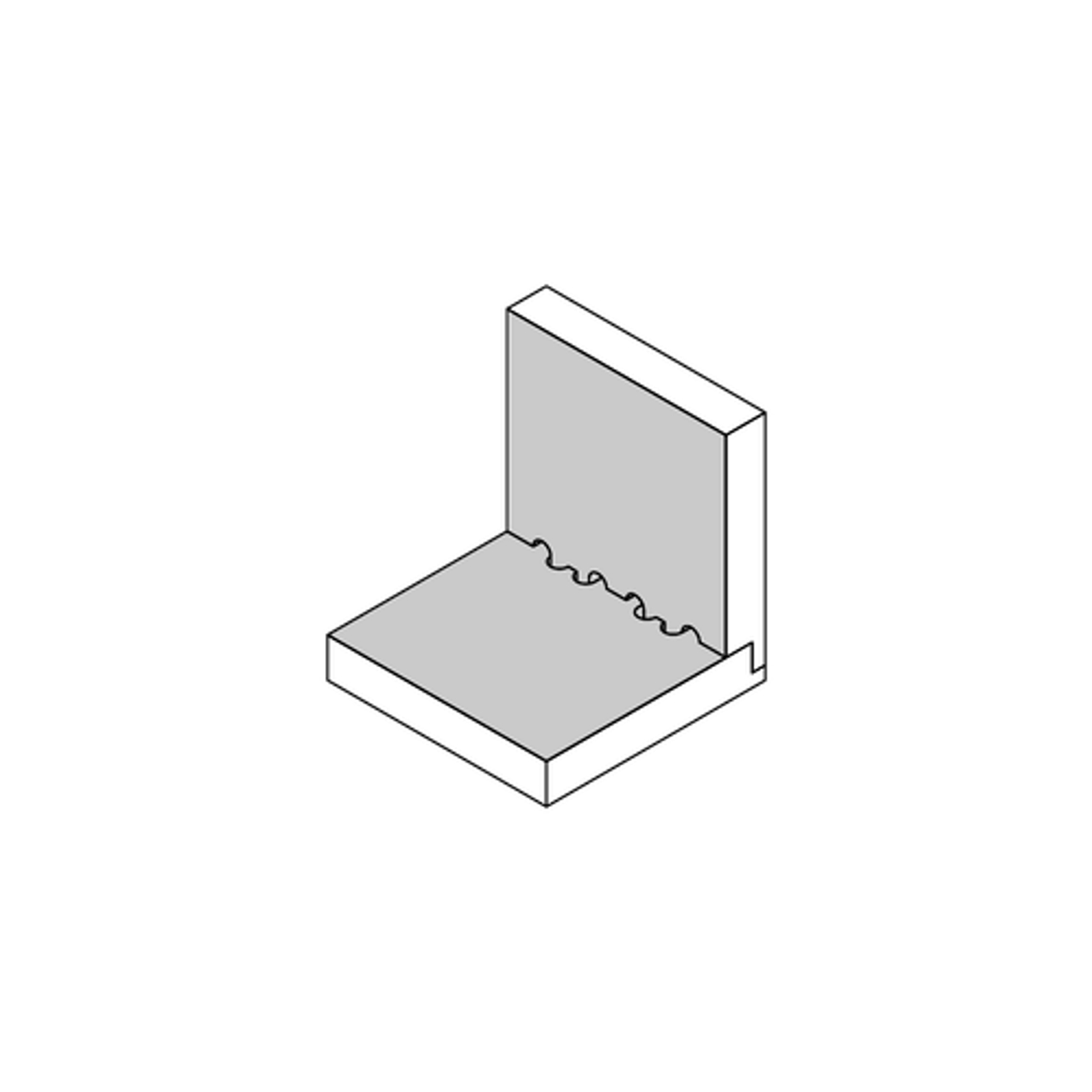

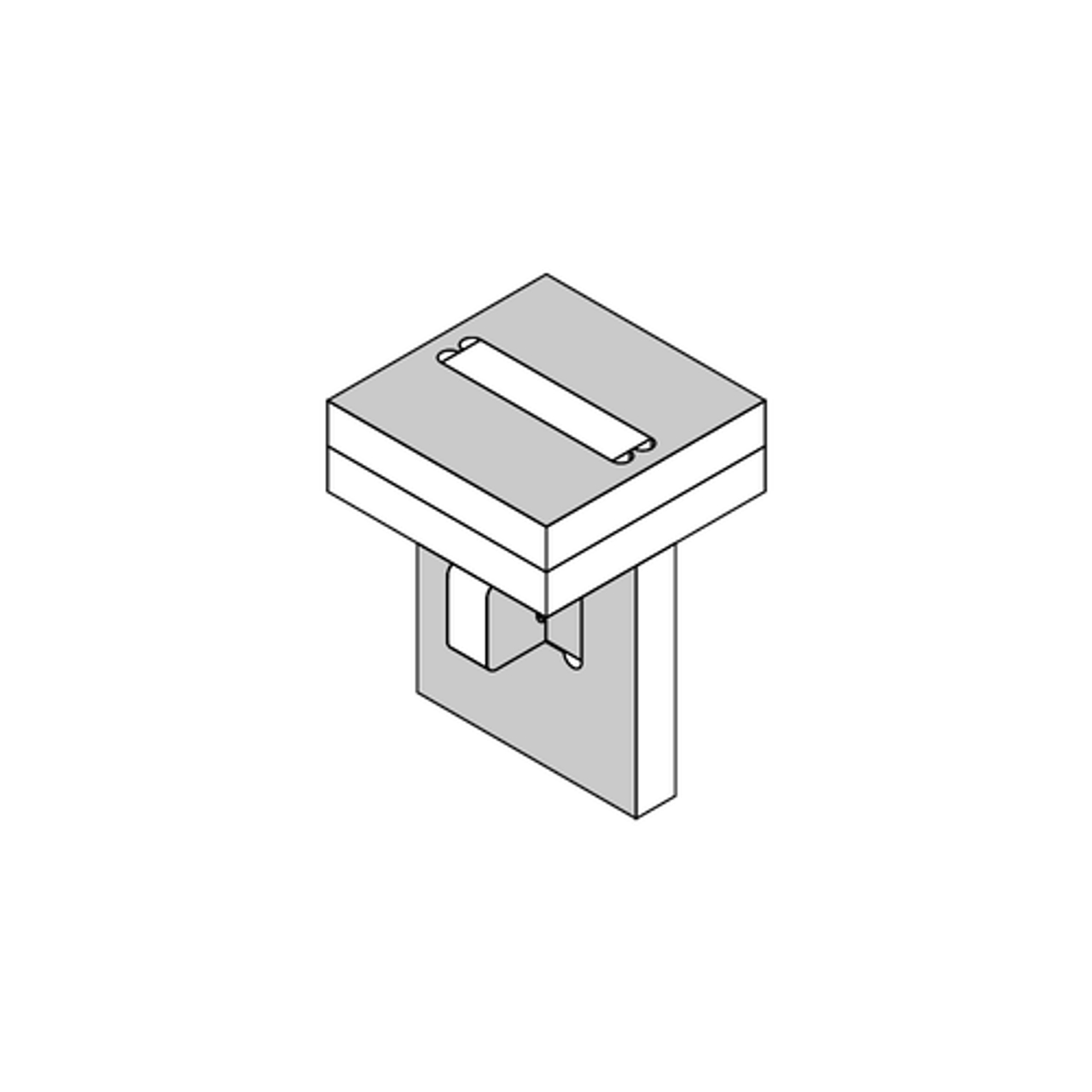

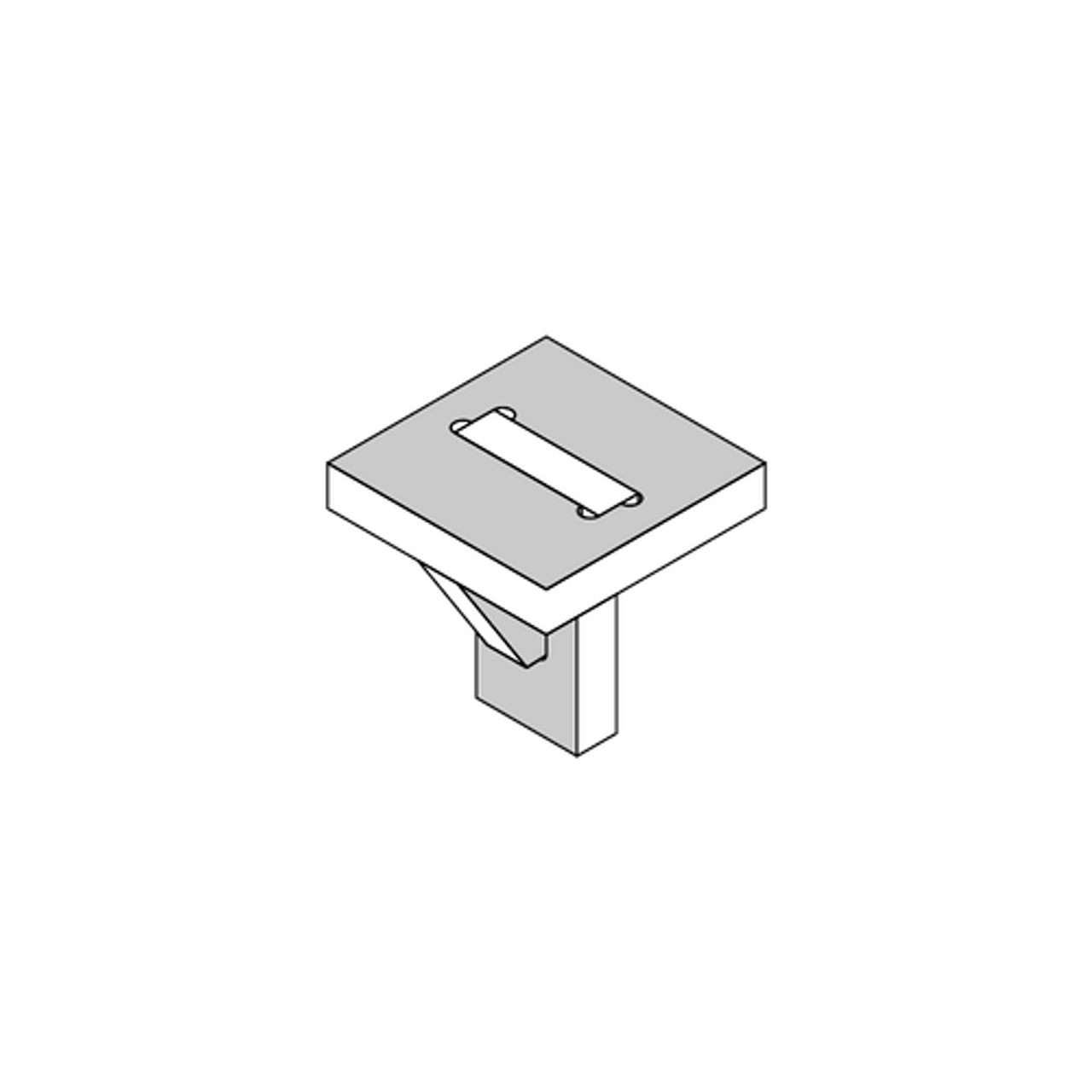

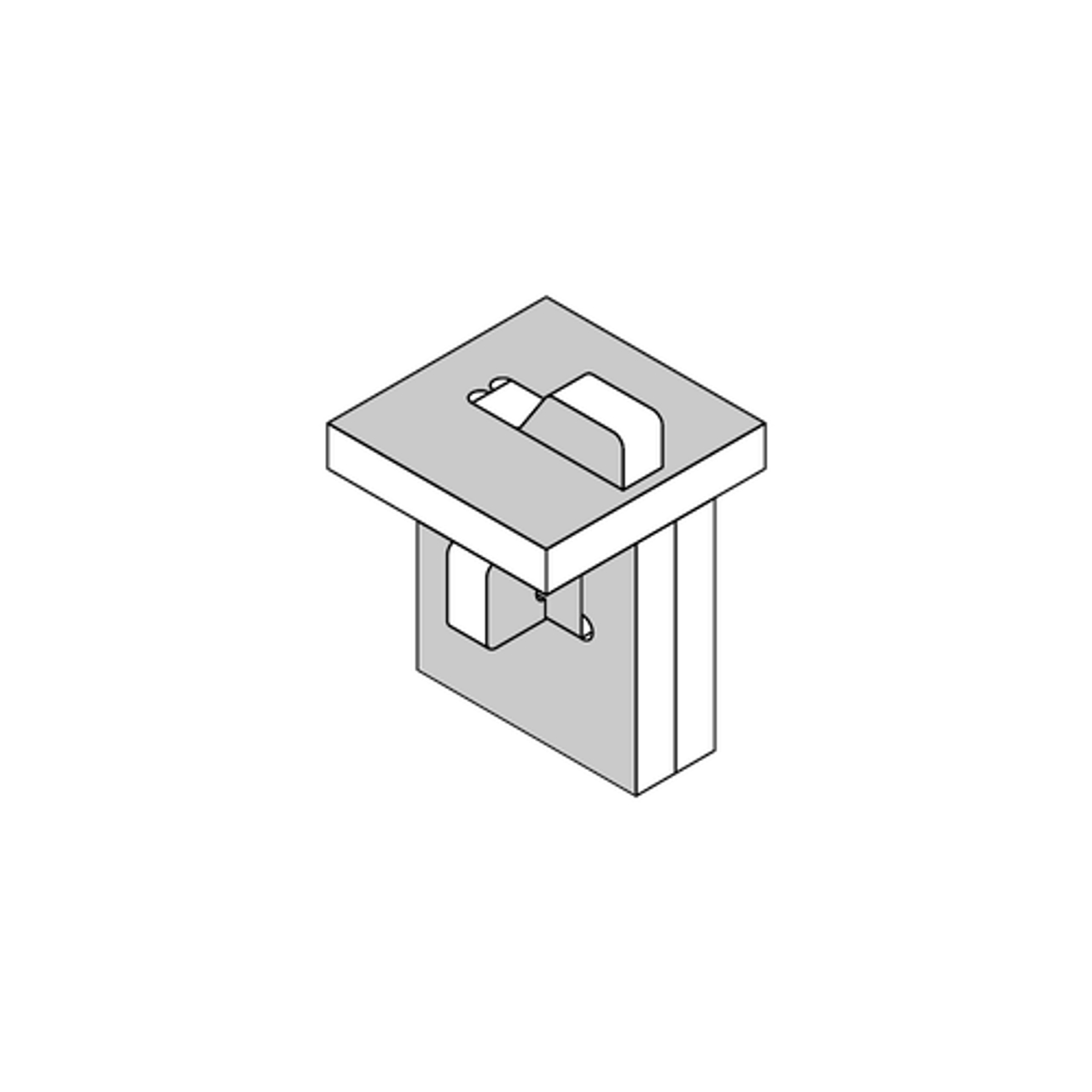

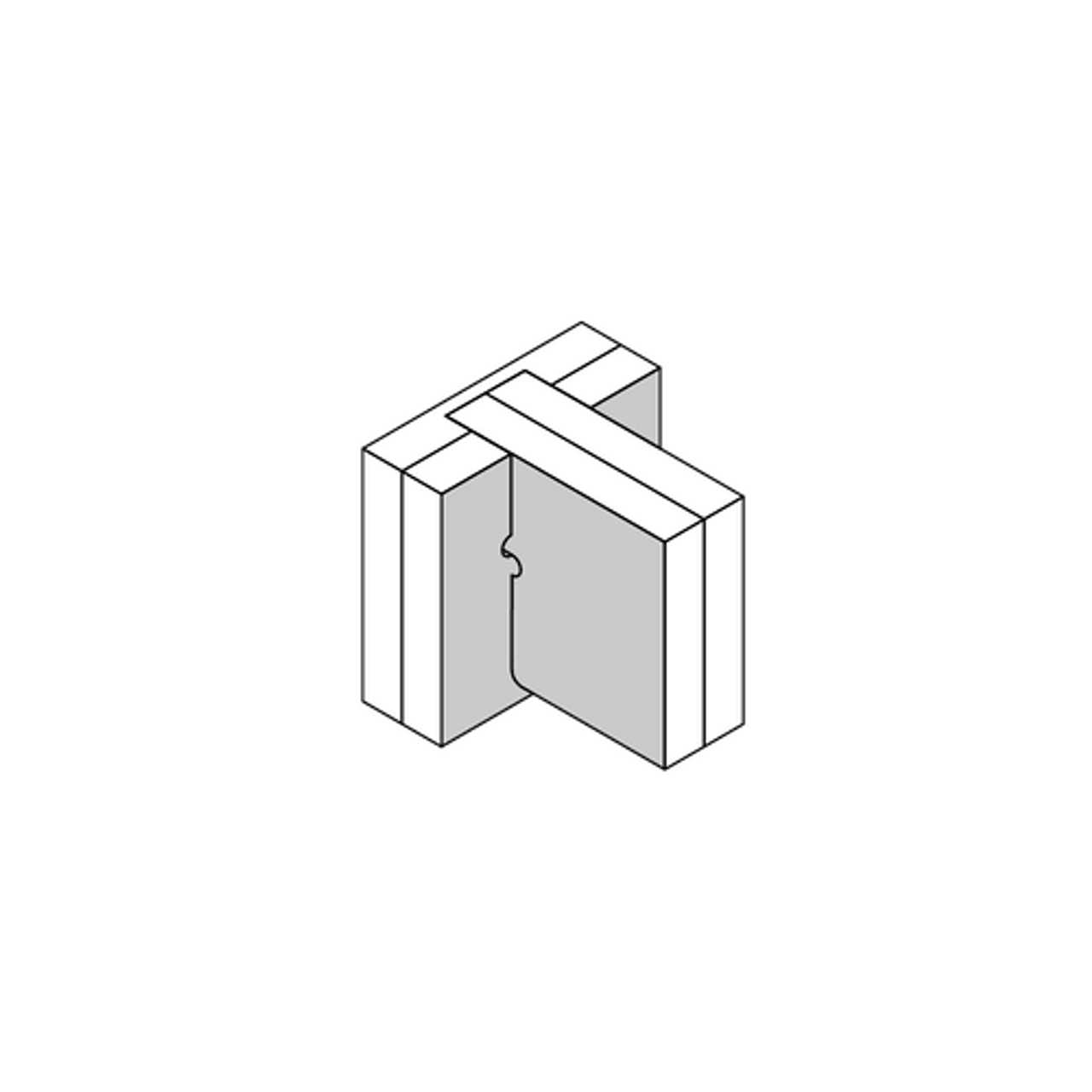

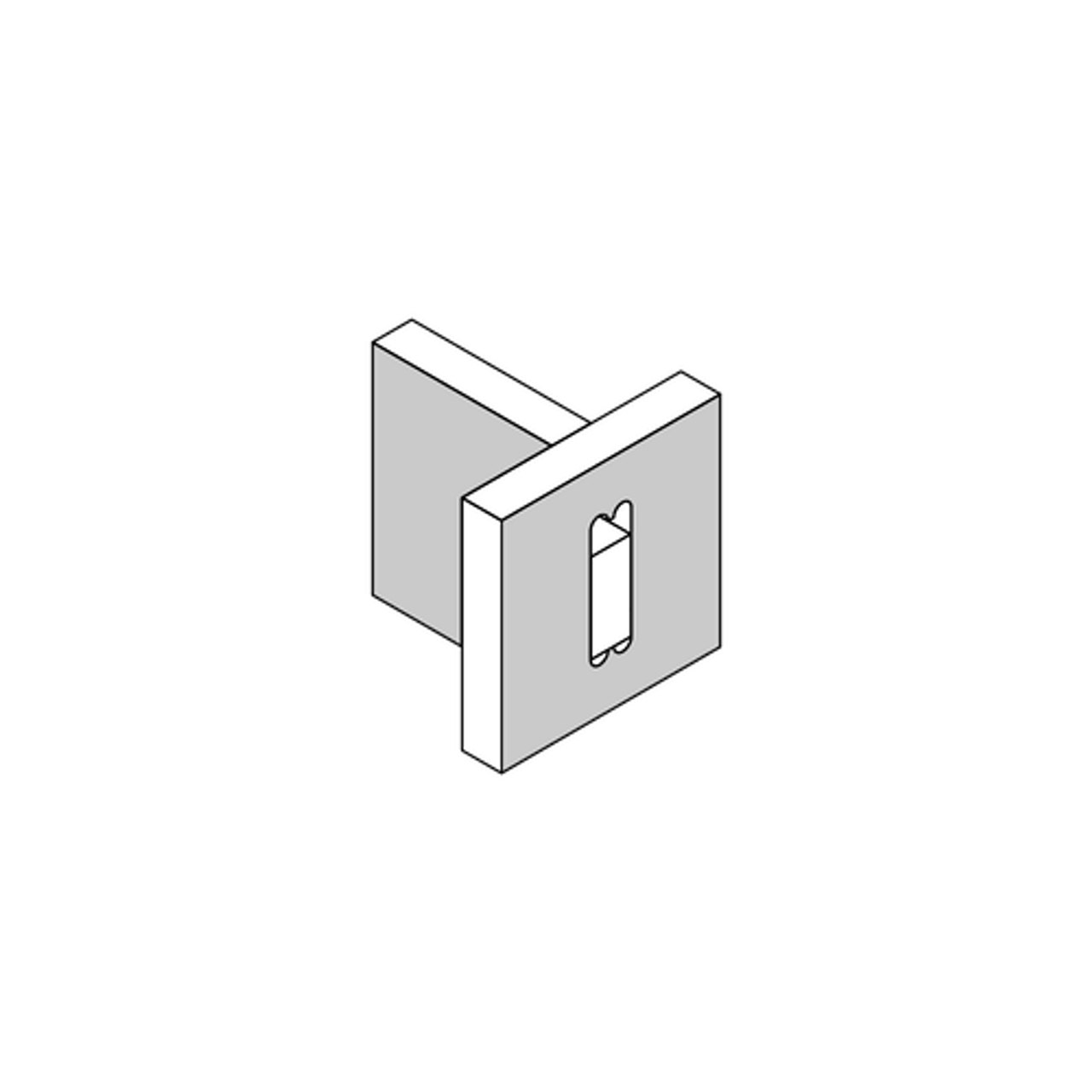

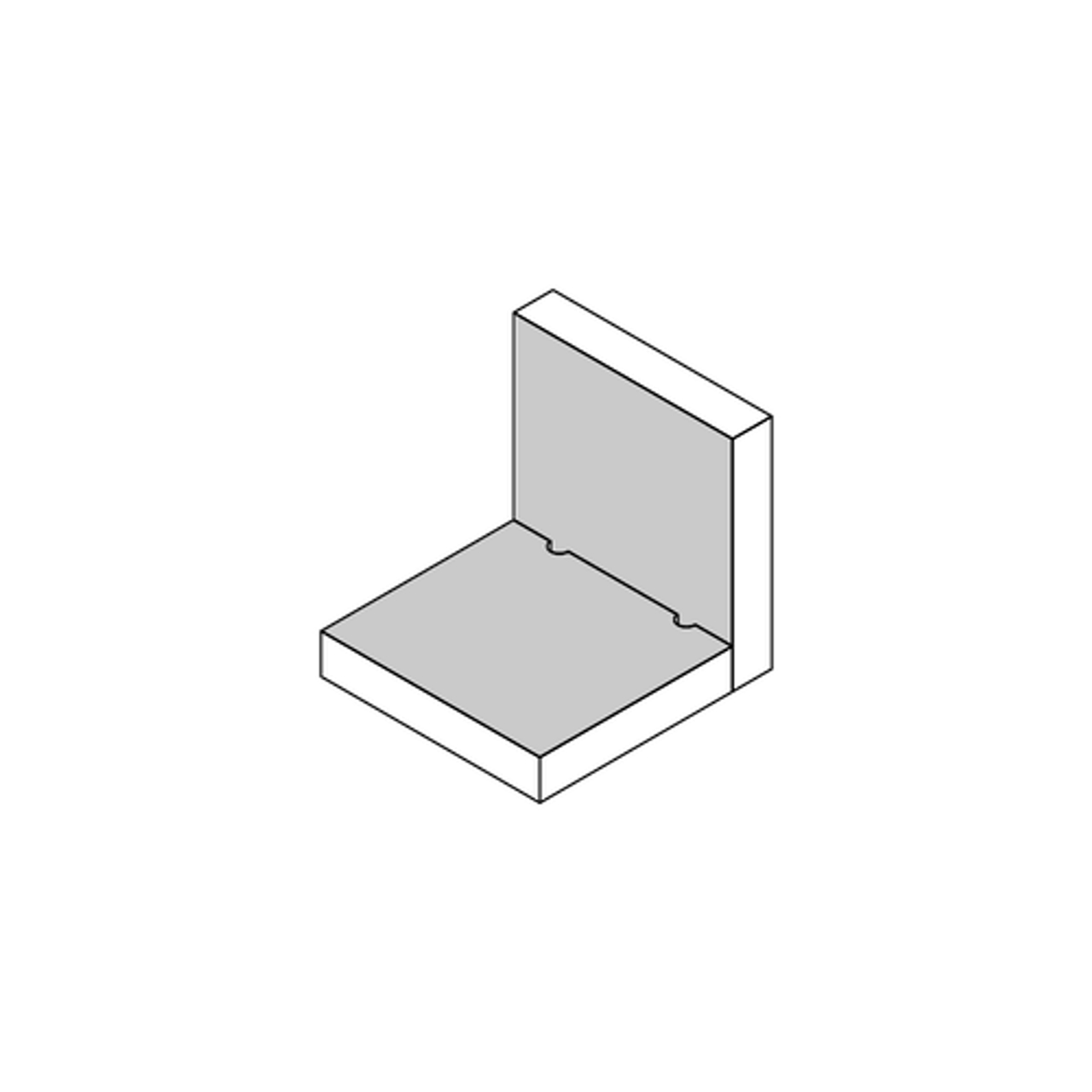

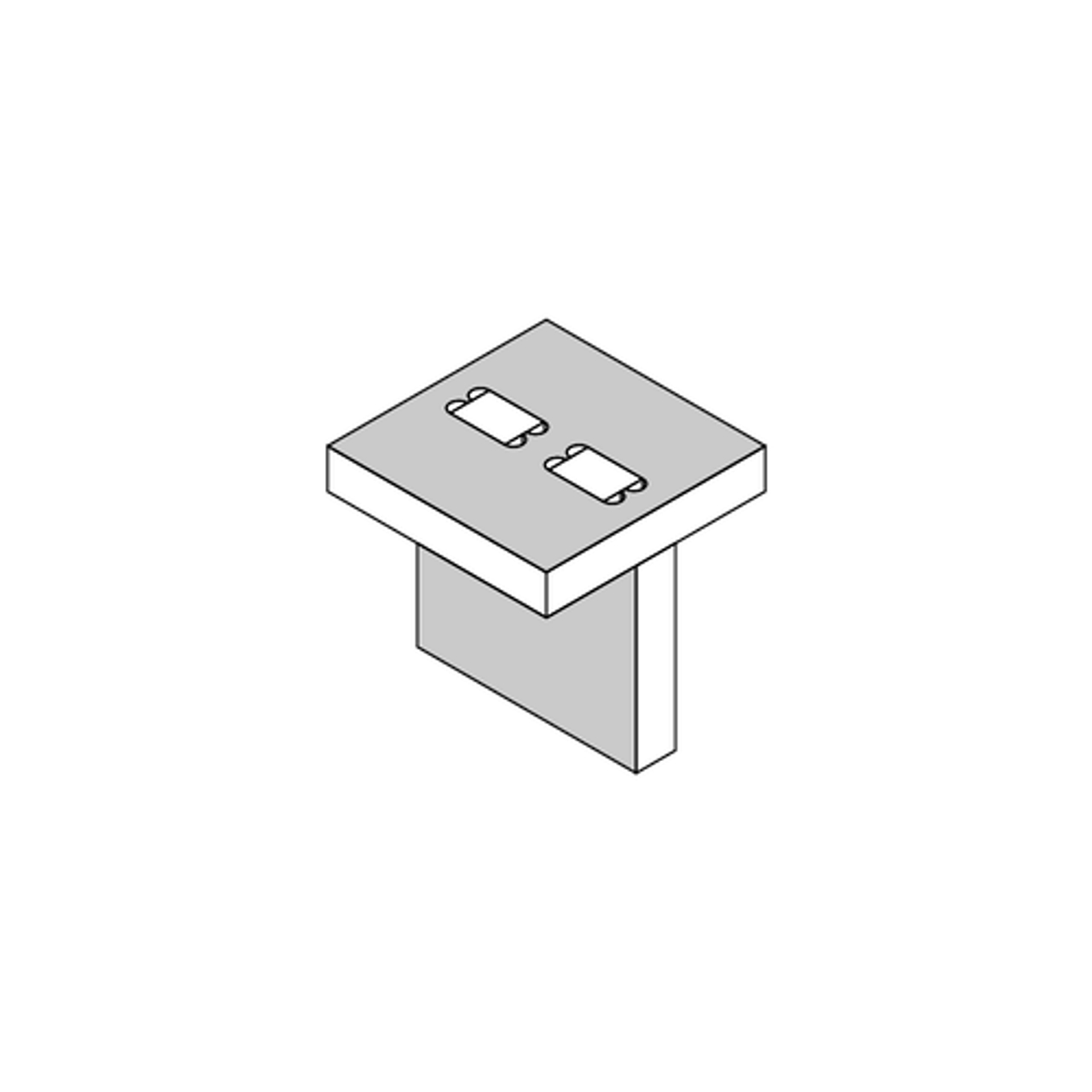

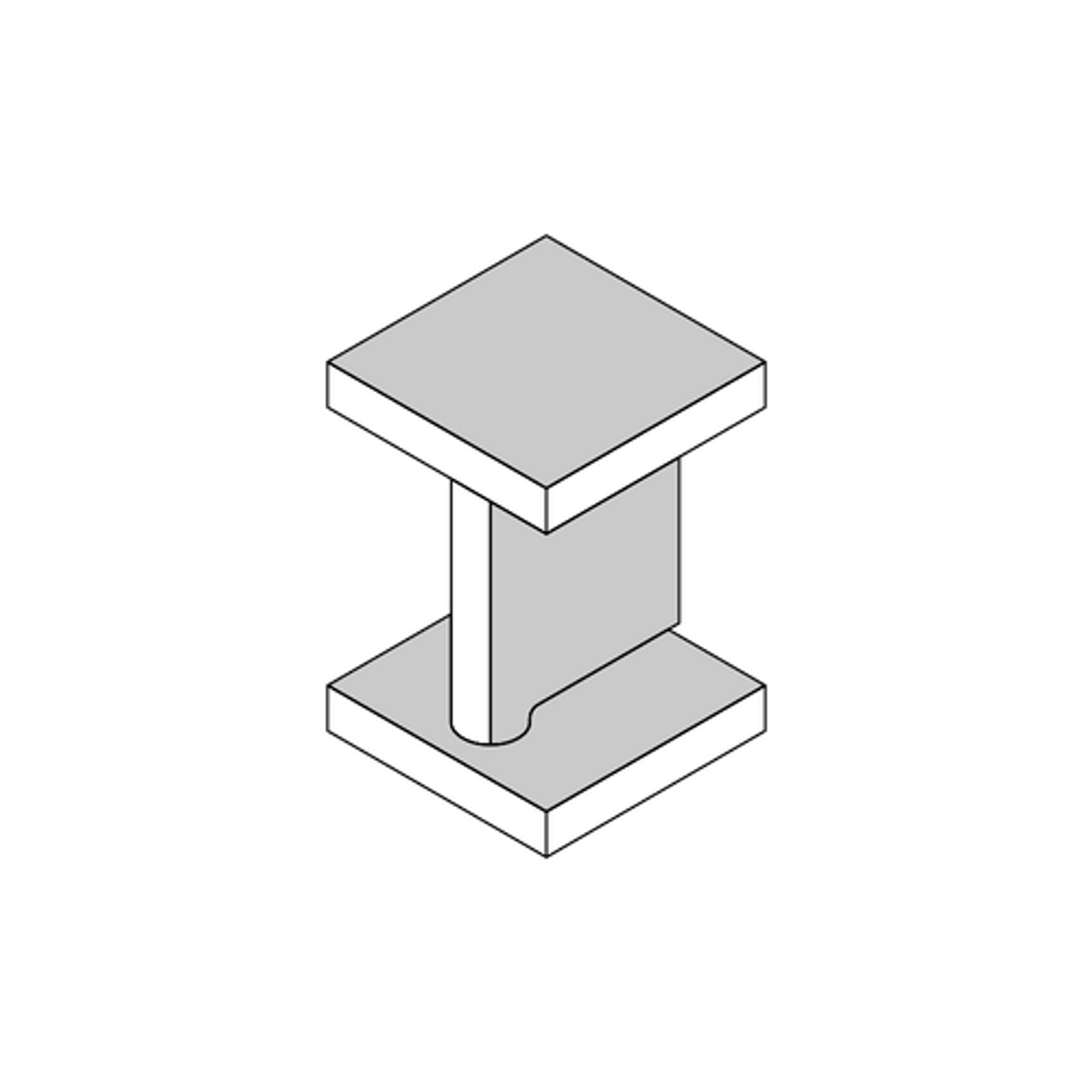

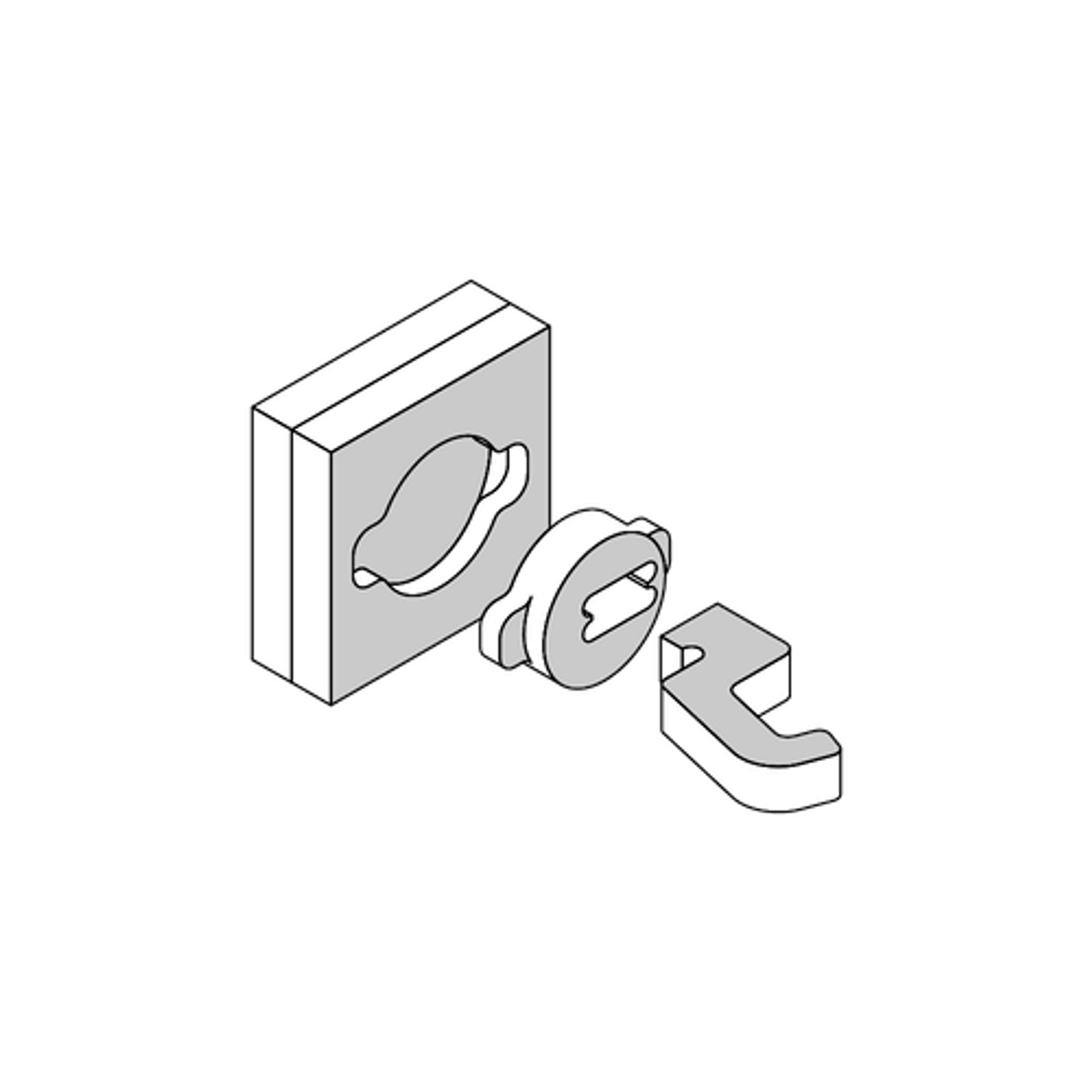

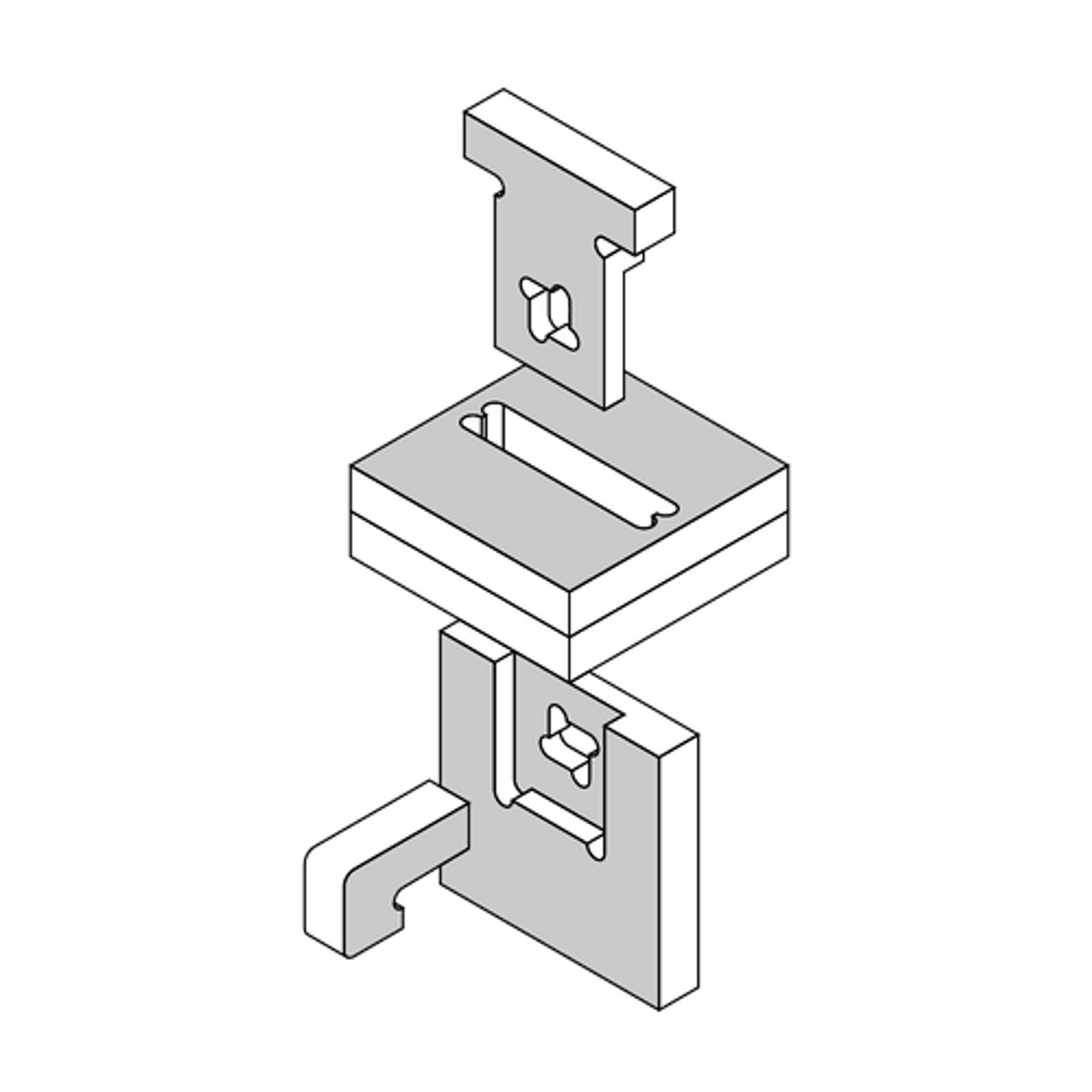

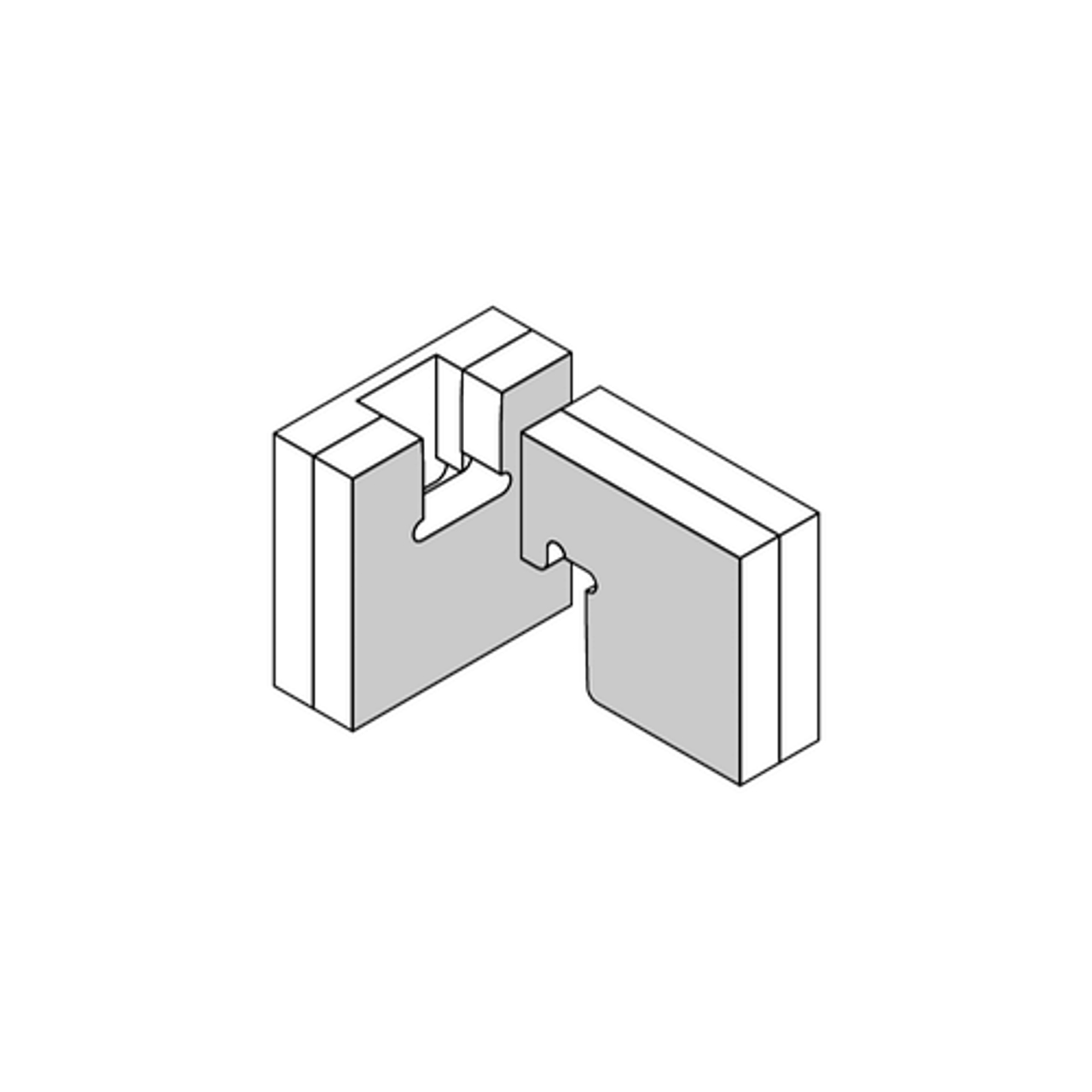

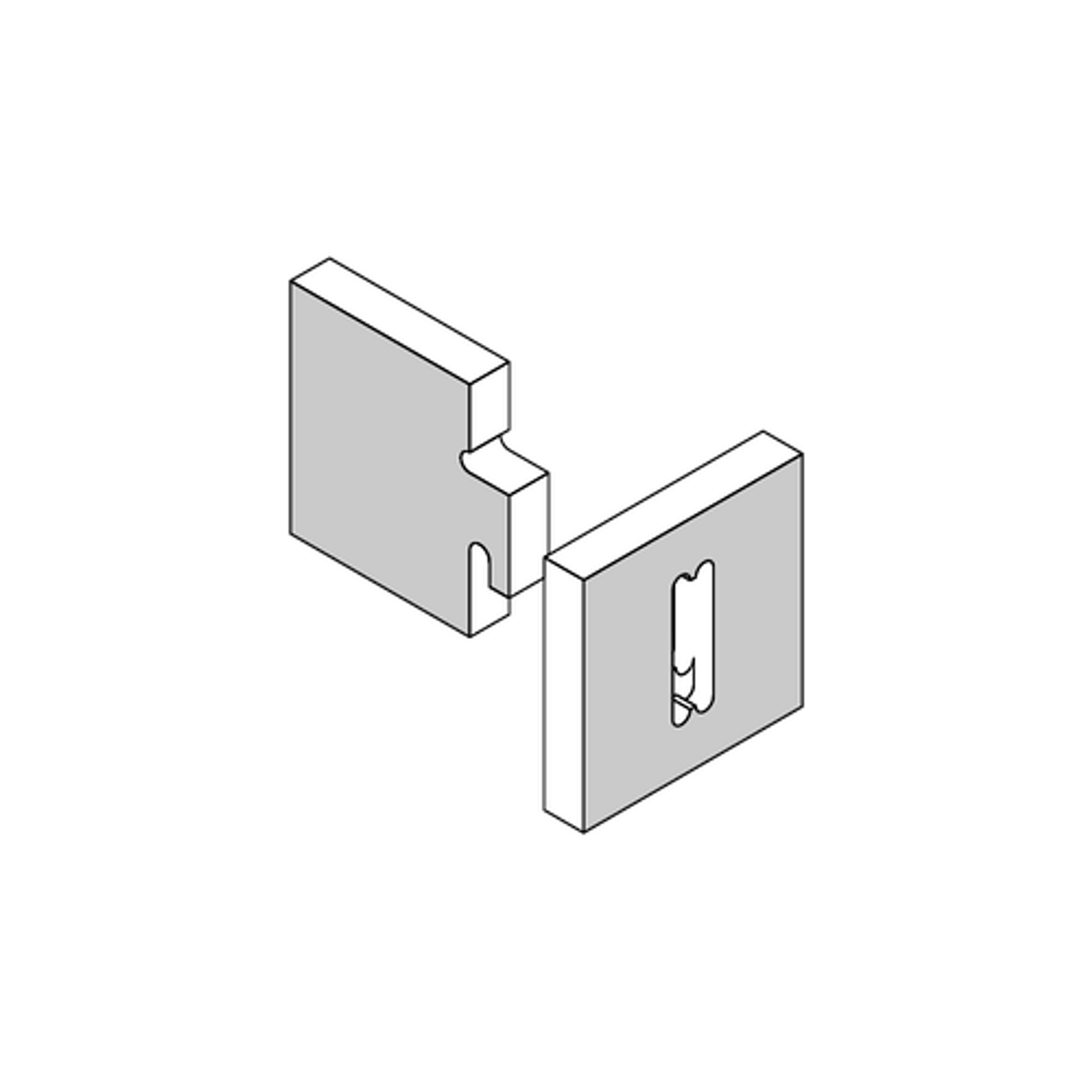

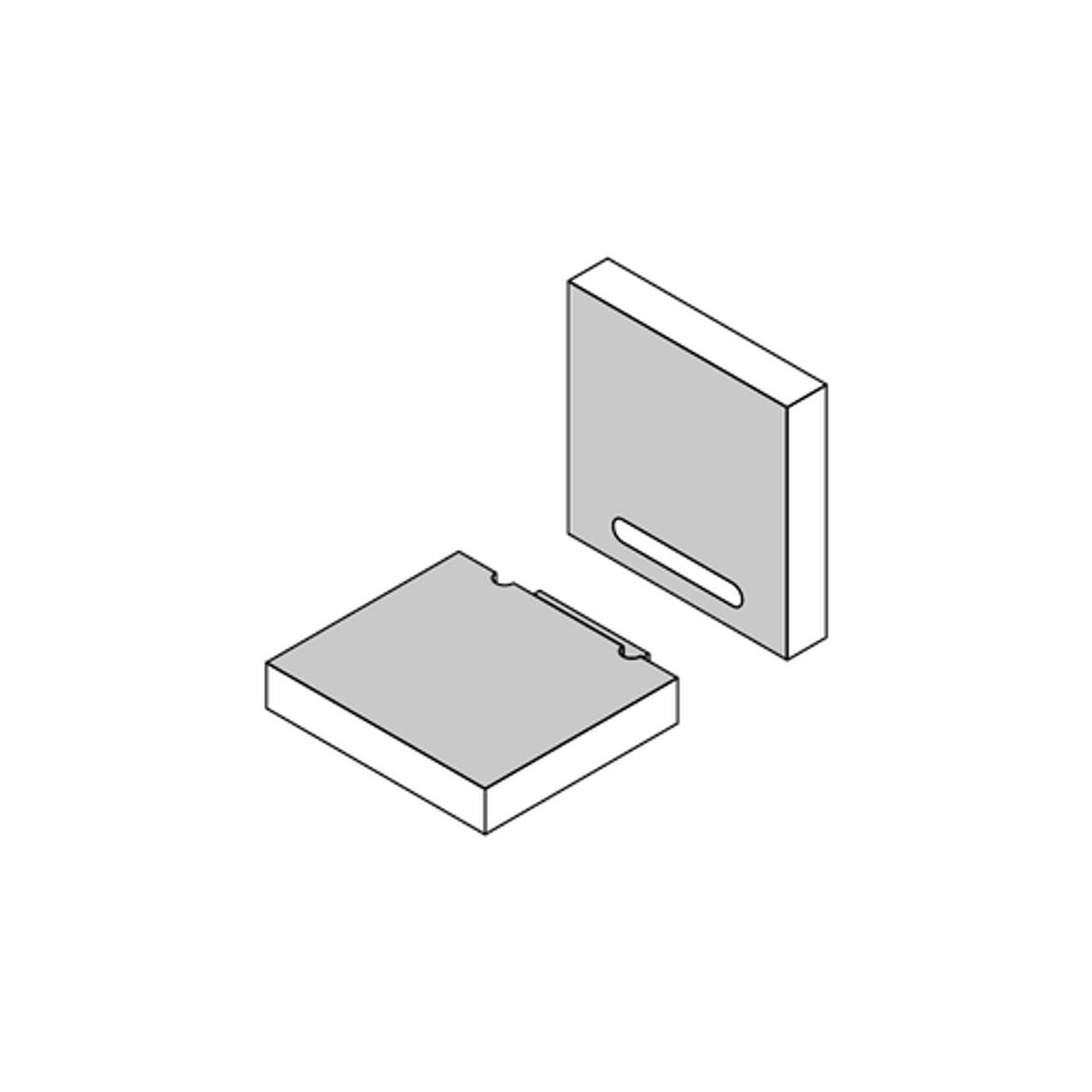

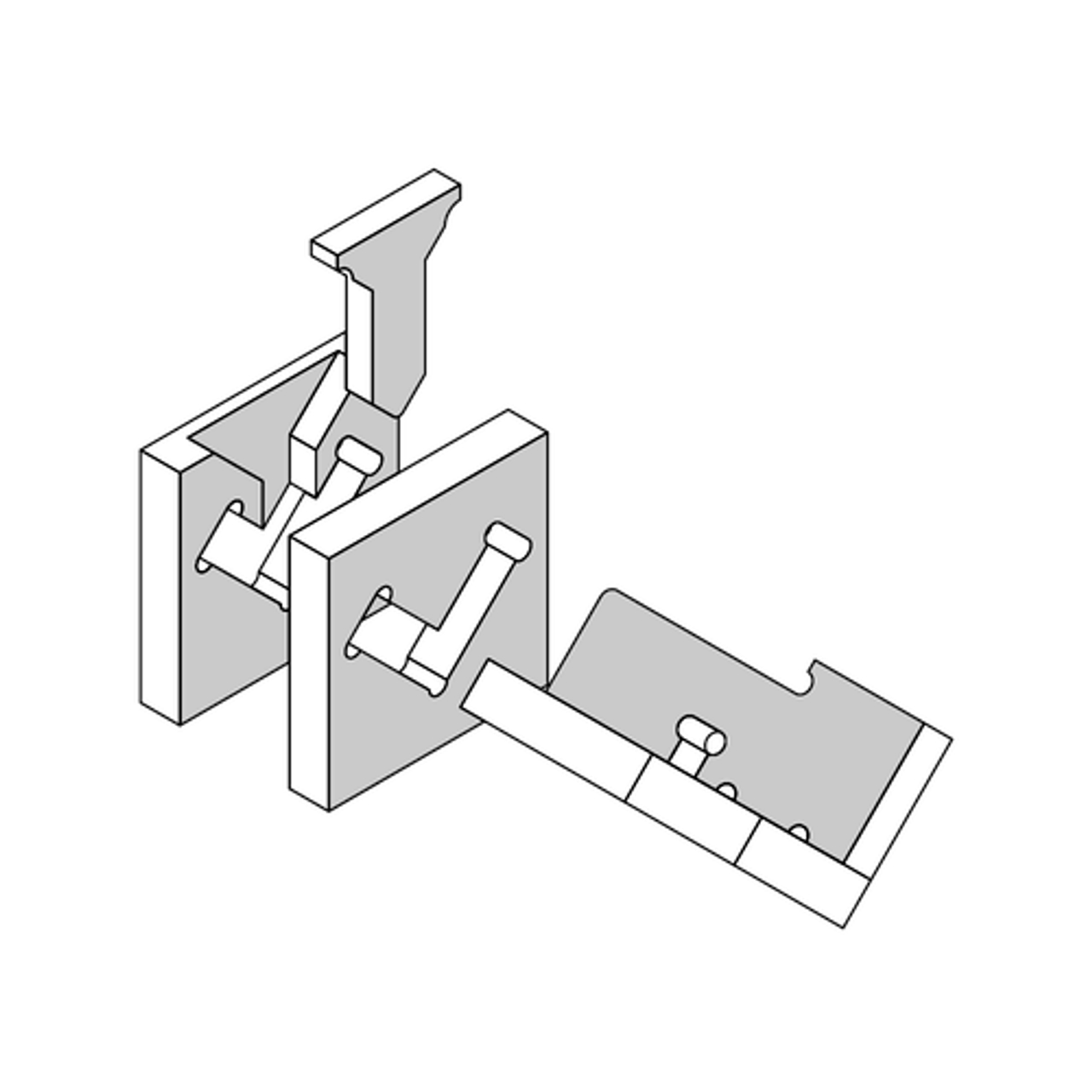

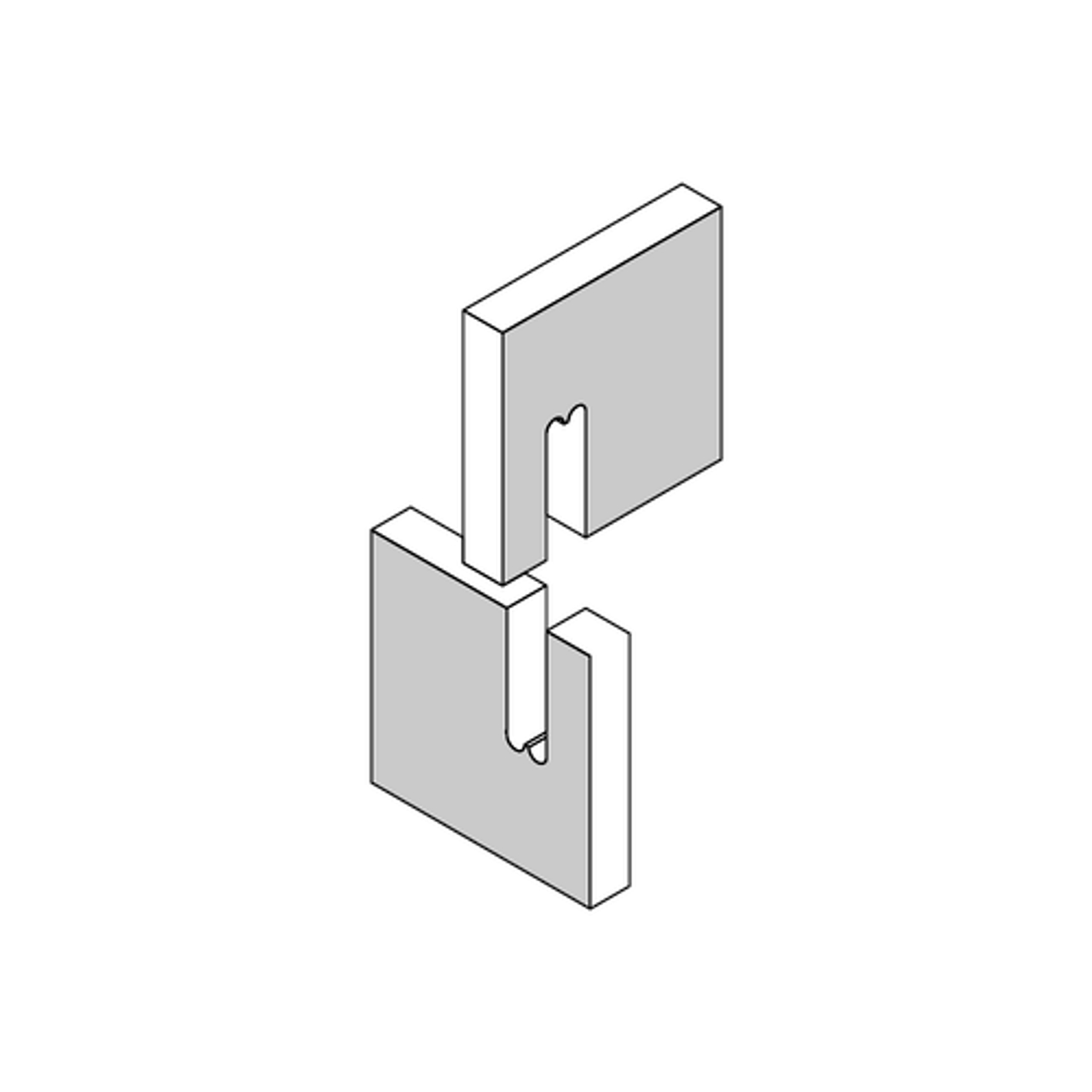

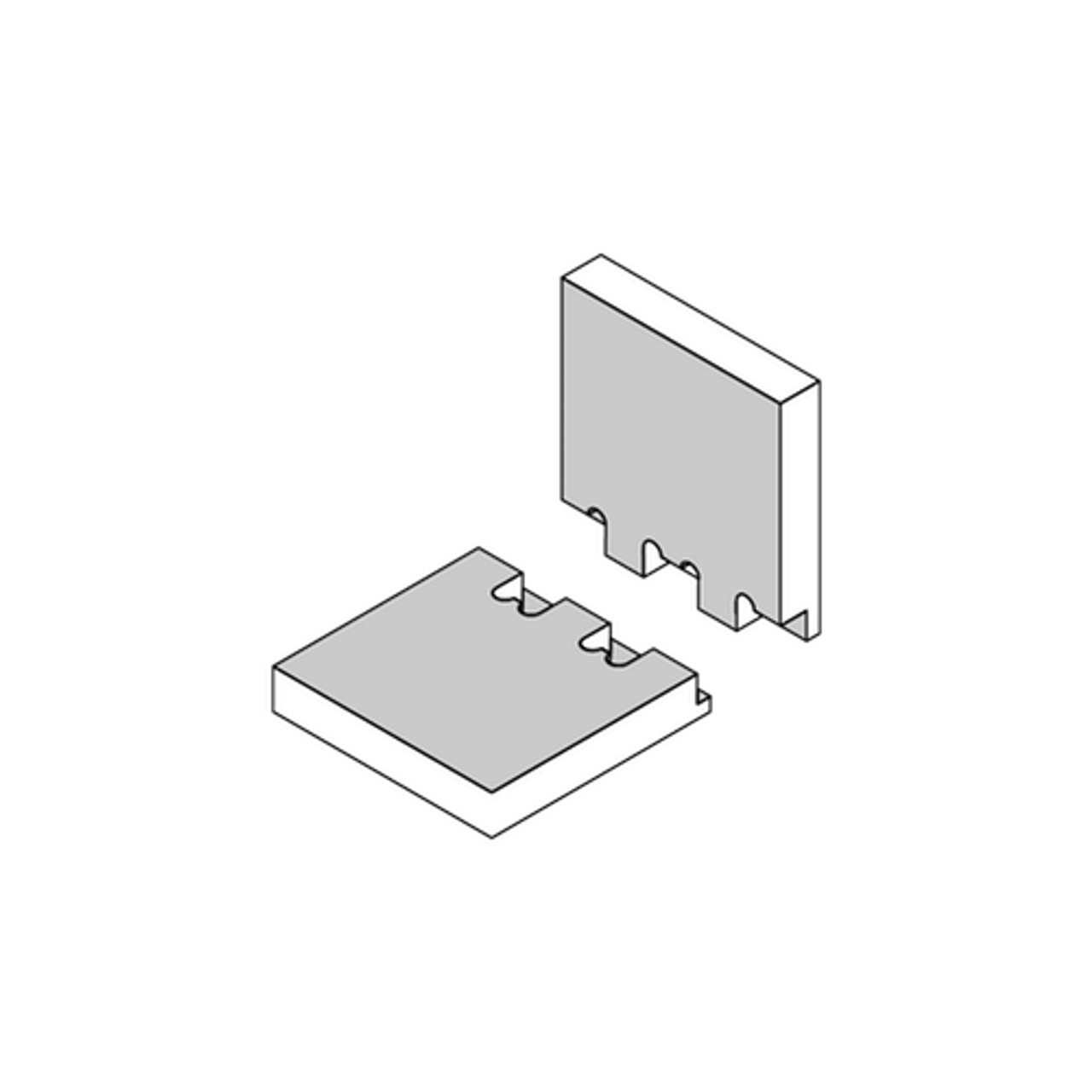

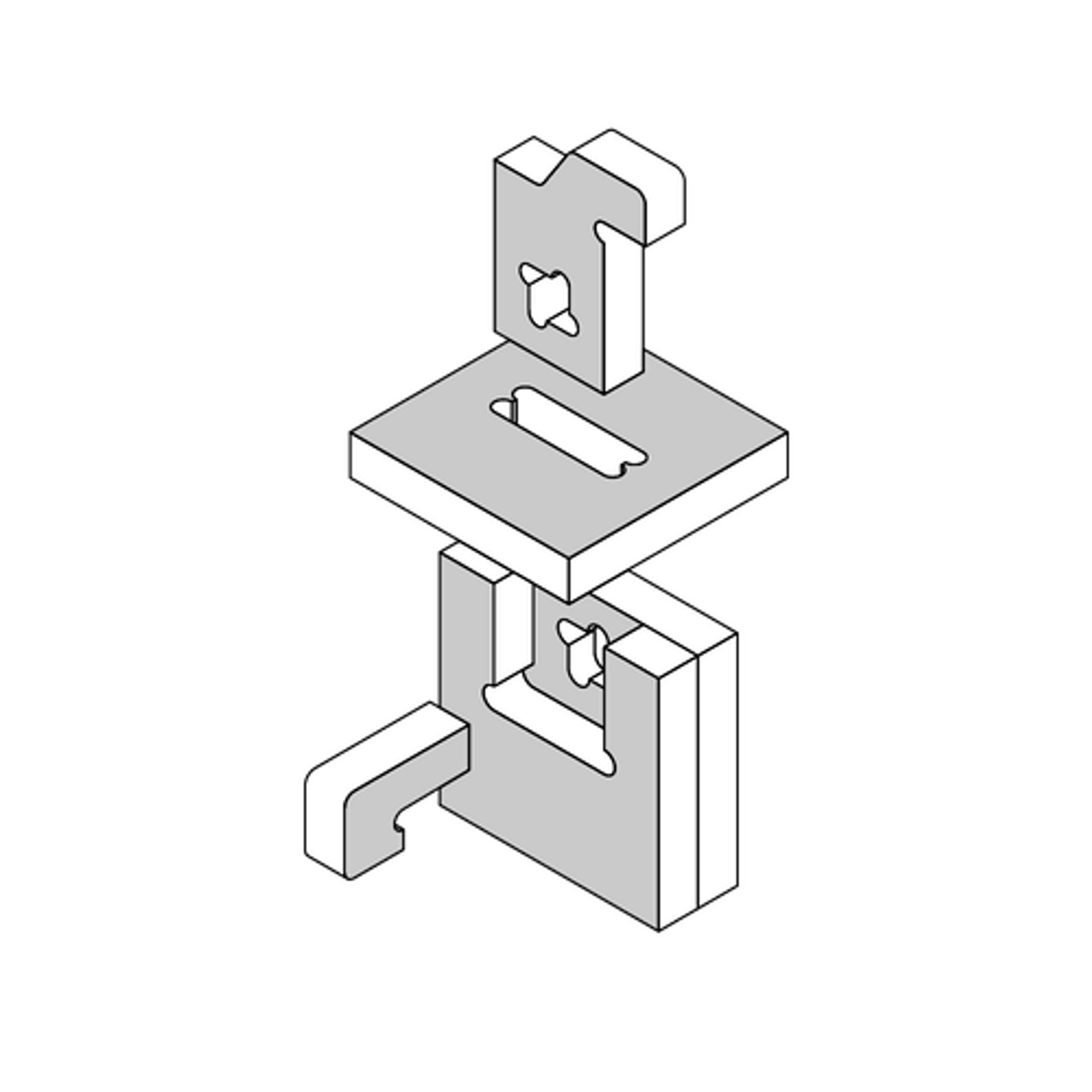

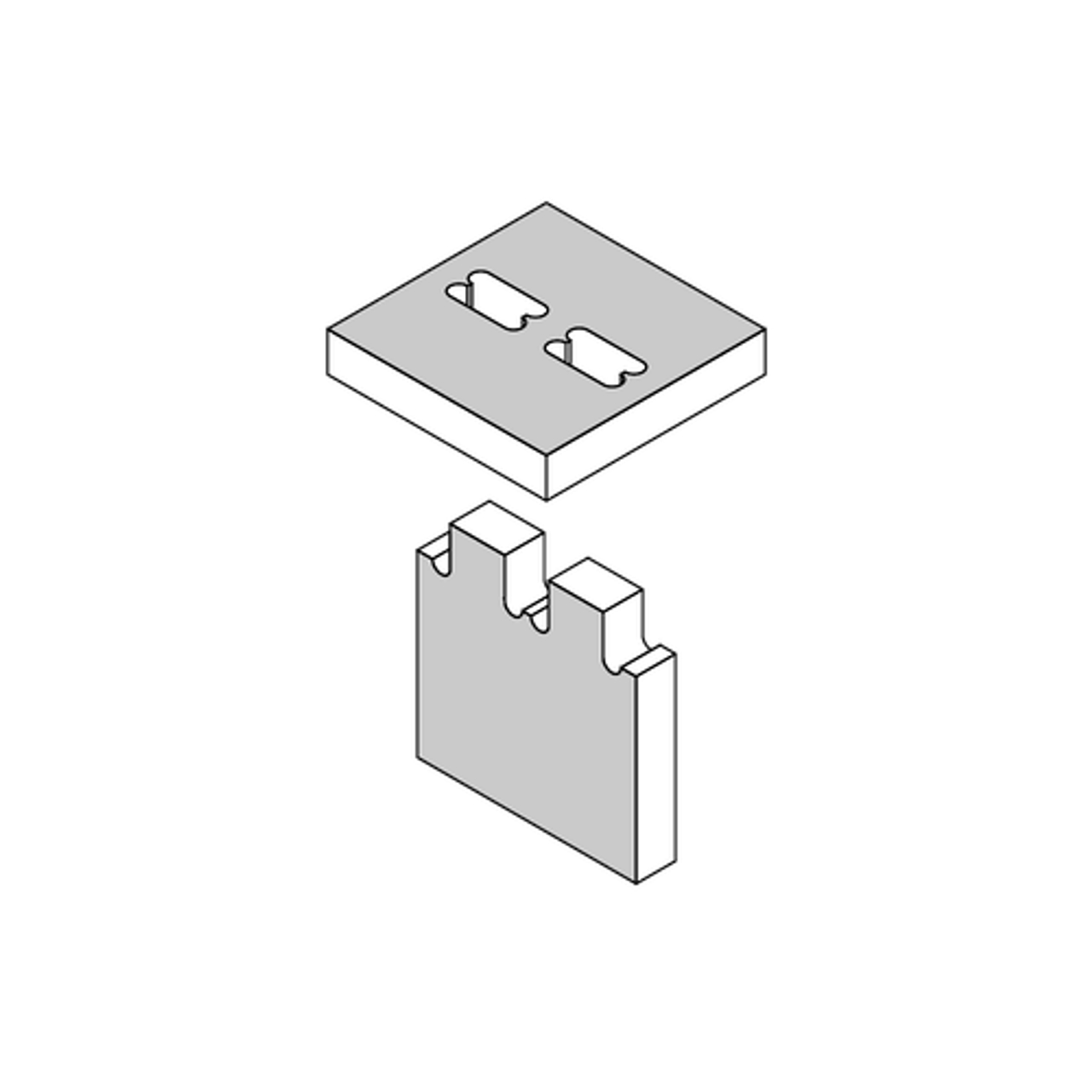

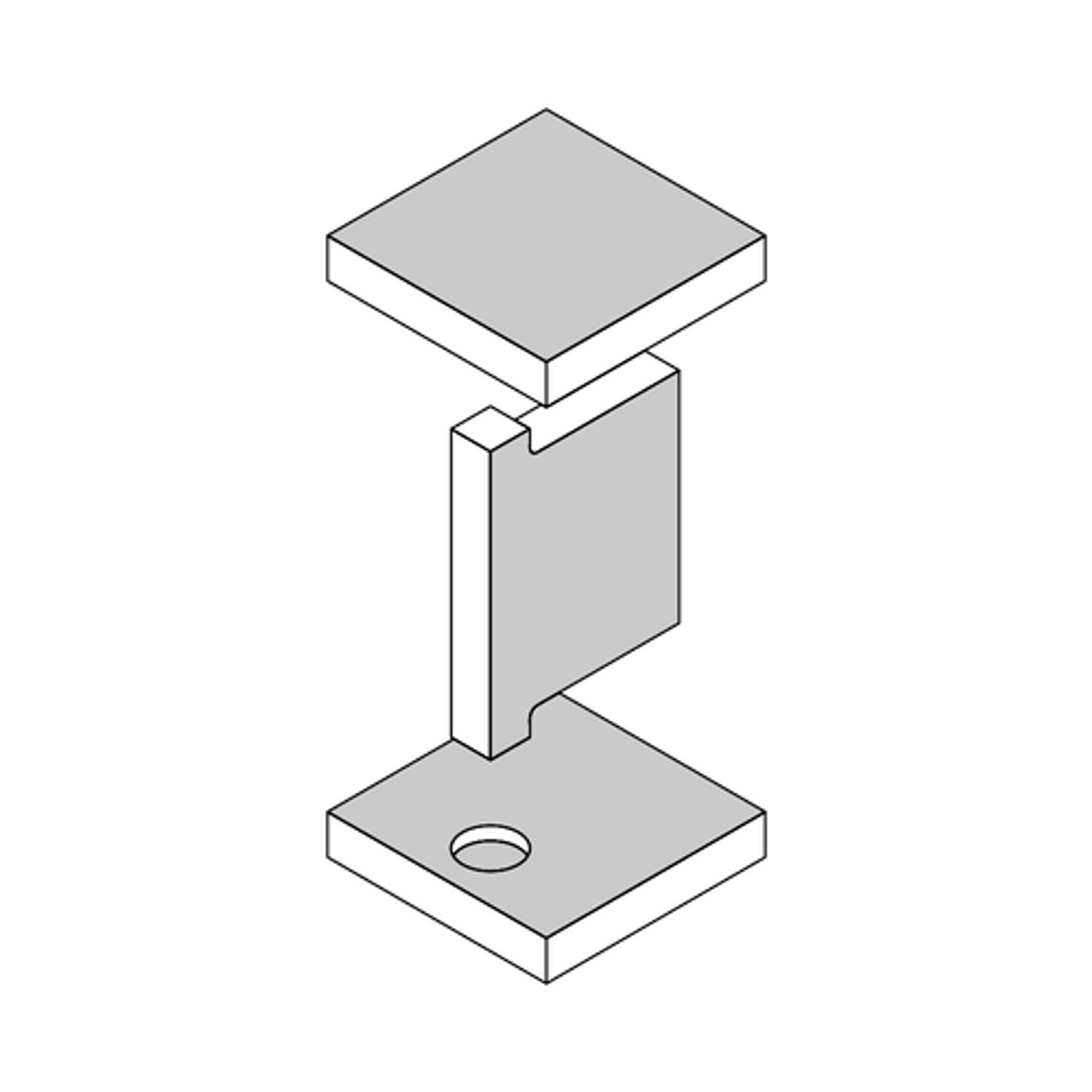

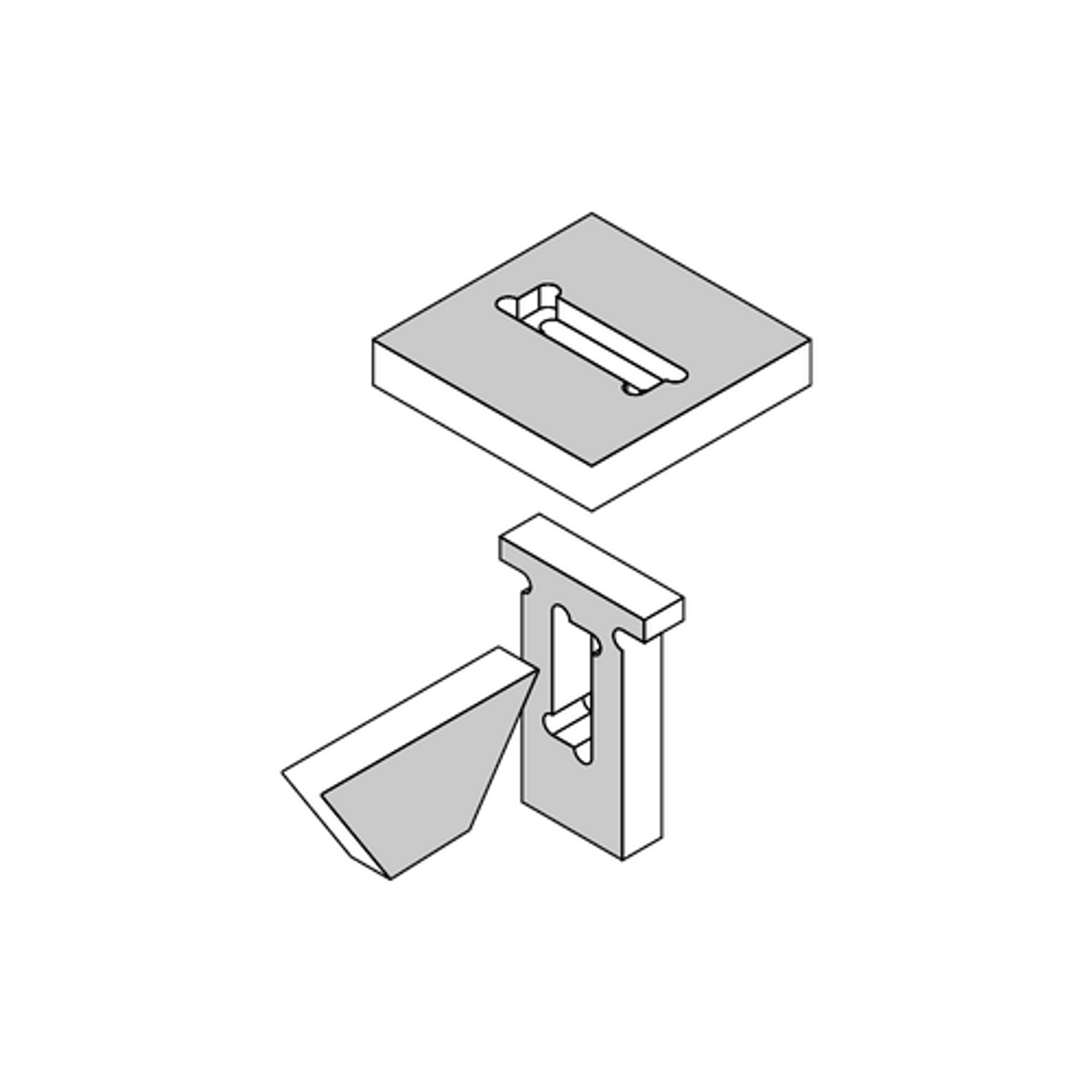

From old classics to new experiments, we list our favourite CNC-made joints including the mortise and tenon and v-clip locking joint.

CNC routers open up a world of possibilities when it comes to intricate wooden joints. Before digital fabrication tools, complex joints were made only by the experienced woodworker, taking many hours to complete. Now, it’s possible to make highly intricate connections in minutes. Here we run through some of our favourite joints from the classic mortise and tenon to the unusual v-clip locking joint.

This post is the second in a series of three design pieces. Read about Designing for CNC milling here and CNC Machines and Common Cut Types here.

Also, if you’re a designer and want to see your design on Opendesk, respond to our latest brief: Open Call for Open Plan!